3-core Power Cord (XLPE insulation)

3-Core Xlpe Electrical Cable

3-Core Xlpe Electrical Cable are usually used in power transmission and distribution systems. It has good conductivity and low resistance, and has strong advantages in power transmission. The design of the three-core cable refers to the IEC60502 CU / XLPE / PVC 0.6 / 1KV specification. Round conductors are suitable for sizes below 16mm², and shaped conductors are suitable for sizes above 35mm² (including 35mm²). We can also provide XLPE insulated three-core wires according to BS7889 requirements.

3-Core Xlpe Electrical Cable: This three-core wire is used to connect electrical appliances (such as lights or extension cables) to power outlets. The cable has three core wires: live wire, ground wire and neutral wire.

Description of 3-core Xlpe cable

Rated temperature: 90℃

Rated voltage: 600/1000V

Reference standard: IEC60502

Conductor: Shaped and round stranded copper conductor

Insulation: XLPE composite insulation

PVC bed

Overall flame retardant PVC sheath

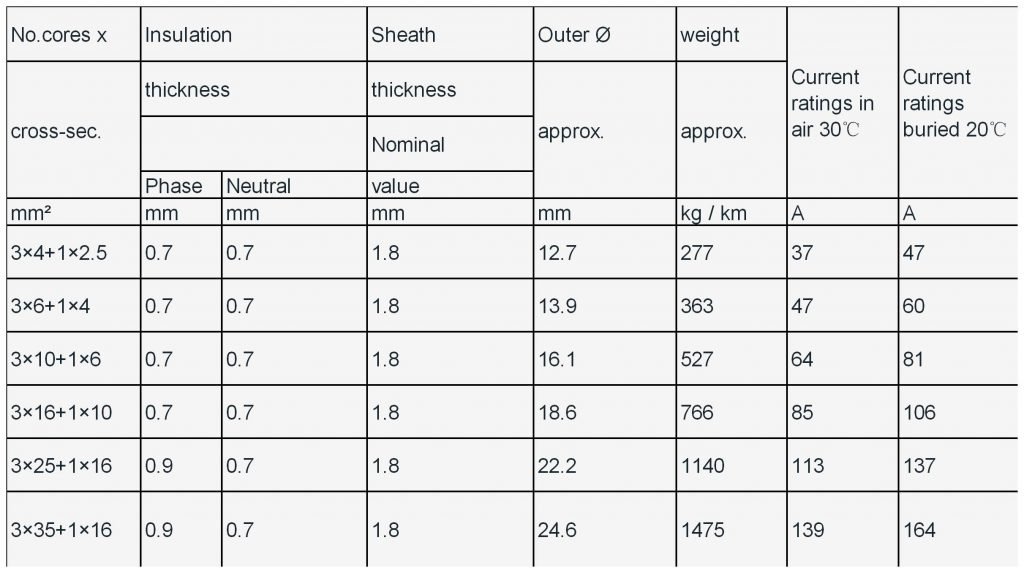

Physical and electrical characteristics

Spatial characteristics of XLPE insulator

The long molecular chains of polyethylene are connected to each other through a process similar to rubber vulcanization, thereby forming a three-dimensional network structure with strong bonds. Pure polyethylene is a thermoplastic material, that is, it will soften and become plastic when heated, and harden when cooled. Pure polyethylene will be converted to thermosetting XLPE, that is, it will permanently solidify after heating. Through the cross-linking process, the polyethylene insulation layer of the cable has thermal stability and the melting point is greatly improved. Therefore, XLPE insulated cables have higher heat resistance and therefore better resistance to thermal deformation. Due to its excellent thermal properties, the current carrying capacity of XLPE cables is higher than that of traditional cables.